Imagine the gentle rocking of your boat, the sun on your face, the wind in your hair… suddenly interrupted by the ominous slosh of water accumulating in your bilge. A chilling scenario, isn’t it? Preventing this nautical nightmare hinges on a crucial element: correctly wired bilge pumps. Understanding the intricacies of bilge pump wiring instructions is not just a good idea, it’s an essential part of responsible boat ownership, fostering peace of mind and ensuring the safety of you, your passengers, and your precious vessel.

Bilge pump wiring isn't about simply connecting a few wires; it’s about understanding the delicate dance of electricity and ensuring a reliable system that will function flawlessly when you need it most. This involves deciphering wiring diagrams, selecting the right components, and adhering to established guidelines. We’ll explore the nuances of this critical system, from basic principles to advanced troubleshooting techniques.

Historically, bilge pumps were manually operated, requiring constant vigilance and physical effort. The advent of electric bilge pumps revolutionized boat safety, offering automatic operation and increased efficiency. This evolution underscored the importance of proper electrical installation, giving rise to standardized bilge pump wiring instructions designed to ensure reliability and prevent hazardous situations. Over time, these instructions have been refined to address various pump types, switch configurations, and alarm systems, reflecting advancements in marine technology.

The most common issues with bilge pump wiring stem from improper connections, corroded wires, or faulty switches. These problems can lead to pump failure, leaving your boat vulnerable to flooding. Understanding the correct bilge pump wiring procedure, including the use of fuses, wire gauge selection, and proper grounding, is paramount in preventing these issues and safeguarding your vessel.

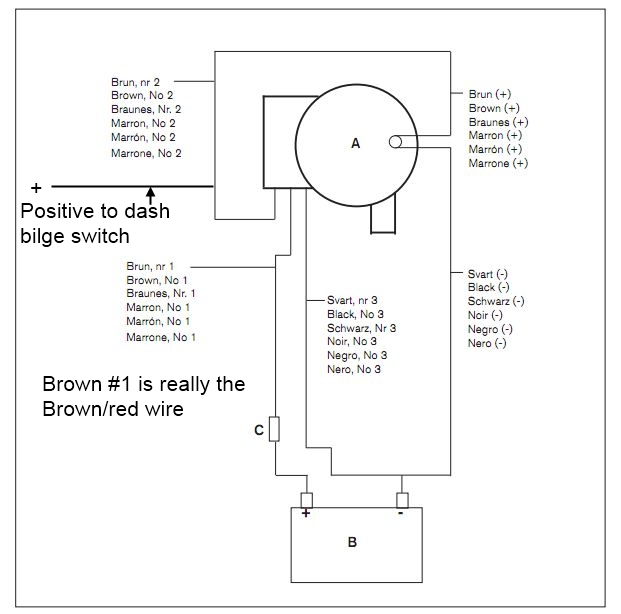

A bilge pump wiring diagram is essentially a roadmap, guiding you through the connections between the pump, float switch, power source, and panel switch. It provides a visual representation of the circuit, indicating wire colors, component locations, and fuse specifications. Decoding this roadmap is fundamental to ensuring a correctly functioning system. For example, a typical diagram will show the positive wire (often red) running from the battery, through a fuse, to the panel switch, and then to the float switch, finally connecting to the pump. The negative wire (often black) typically runs directly from the battery to the pump.

Benefits of following bilge pump wiring instructions are threefold: First, safety. Correct wiring ensures the pump functions reliably, protecting your boat from flooding. Second, longevity. Proper installation minimizes wear and tear on the pump and electrical components, extending their lifespan. Third, peace of mind. Knowing your bilge pump system is correctly wired allows you to enjoy your time on the water without worrying about potential flooding.

Creating an action plan for your bilge pump wiring involves several steps. First, gather the necessary materials: the pump, float switch, wiring, fuses, and connectors. Second, consult the wiring diagram specific to your pump model. Third, meticulously follow the instructions, ensuring proper connections and grounding. A successful example would be a bilge pump that automatically activates when water reaches a certain level, efficiently removing the water and then shutting off once the bilge is dry.

A simple checklist for bilge pump wiring includes: verify correct wire gauge, check fuse rating, ensure proper grounding, test float switch operation, and confirm panel switch functionality.

A step-by-step guide could include: disconnect battery, connect float switch wires, connect pump wires, connect power wires through the fuse, connect to the panel switch, reconnect battery, test the system.

Advantages and Disadvantages of Different Bilge Pump Wiring Approaches

While a fully automatic system is generally preferred, manual bilge pumps offer a backup in case of electrical failure.

Best practices for bilge pump wiring include: using marine-grade wiring, installing an inline fuse, ensuring proper grounding, using waterproof connectors, and regularly inspecting the system for corrosion or damage.

A real-world example involves a sailboat owner who experienced a leak during a storm. His correctly wired bilge pump automatically activated, preventing the boat from sinking. This highlights the life-saving potential of a properly installed bilge pump system.

A common challenge is diagnosing a faulty float switch. The solution often involves testing the switch with a multimeter to ensure continuity.

FAQ: 1. What wire gauge should I use? Answer: Consult your pump's specifications. 2. Where should I install the float switch? Answer: In the lowest part of the bilge. 3. Do I need a fuse? Answer: Absolutely, to protect the circuit. 4. What type of connectors should I use? Answer: Marine-grade, waterproof connectors. 5. How often should I inspect my bilge pump? Answer: Regularly, at least annually. 6. What should I do if my pump isn't working? Answer: Check the fuse, wiring, and float switch. 7. Can I install multiple bilge pumps? Answer: Yes, for added safety and capacity. 8. Should I have a manual bilge pump as a backup? Answer: Yes, it's highly recommended.

Tips and tricks for bilge pump wiring include using dielectric grease on connections to prevent corrosion and labeling wires for easy identification.

In conclusion, mastering the art of bilge pump wiring instructions is a non-negotiable aspect of responsible boat ownership. It’s not just about following a set of rules; it's about understanding the principles behind those rules and applying them diligently. A correctly wired bilge pump is an investment in safety, peace of mind, and the longevity of your vessel. By taking the time to understand the nuances of bilge pump wiring, you empower yourself to protect your boat and ensure countless worry-free hours on the water. Don't just react to a flooding bilge; proactively prevent it. Take the time to review your bilge pump system today, consult your owner's manual, and if in doubt, seek professional assistance. Your boat, and your peace of mind, will thank you.

Gridiron guessing game decoding espns nfl week 5 predictions

Dead battery costco cat jump starters your roadside savior

The art of coordinated discord names weaving identity and connection in the digital tapestry

Rule Bilge Wiring Diagram - You're The Only One I've Told

DIAGRAM 3 Way Switch Wiring Diagrams With Float Switch Bilge Pump - You're The Only One I've Told

rule bilge pump wiring instructions - You're The Only One I've Told

Rule Bilge Pump Wiring Instructions - You're The Only One I've Told

Rule Bilge Pump Wiring Schematic - You're The Only One I've Told

How To Hook Up A Bilge Pump Switch at Marilyn Thomas blog - You're The Only One I've Told

Wiring Diagram Manual Bilge Pump - You're The Only One I've Told

Rule Bilge Pump Switch Wiring Diagram - You're The Only One I've Told

Automatic Bilge Pump Wiring Diagram - You're The Only One I've Told

Automatic Bilge Pump Wiring - You're The Only One I've Told

Rule Automatic Bilge Pump Wiring Diagram - You're The Only One I've Told

How To Wire A Float Switch For A Bilge Pump at James Belcher blog - You're The Only One I've Told

How To Wire A Rule Bilge Pump - You're The Only One I've Told

rule bilge pump wiring instructions - You're The Only One I've Told

The Complete Guide to Wiring a Johnson Automatic Bilge Pump Step - You're The Only One I've Told