Ever feel that surge of power – literally – when wielding a drill or firing up a circular saw? Power tools are amazing for tackling DIY projects and professional tasks, but they also demand respect. Mishandling these powerful instruments can lead to serious injury. That's why understanding and implementing power tool safety tips is absolutely crucial, whether you're a seasoned pro or a weekend warrior.

Power tool safety isn't just about avoiding trips to the ER; it's about empowering yourself to work confidently and effectively. By following proper procedures, you'll not only protect yourself but also improve the quality and precision of your work. Think of it this way: safety isn't a hindrance; it's the foundation for success in any project involving power tools.

The history of power tools is intertwined with the evolution of electricity and engineering. Early power tools were often bulky and dangerous, lacking the safety features we take for granted today. As technology advanced, so did the focus on operator safety, leading to the development of features like guards, safety switches, and ergonomic designs. Understanding this evolution underscores the importance of utilizing these built-in safeguards.

One of the main issues surrounding power tool safety is complacency. It's easy to become overconfident or to rush through a project, neglecting basic precautions. Another significant problem is inadequate training. Many individuals use power tools without proper instruction, leading to unsafe practices and increased risk of accidents. Addressing these issues through education and awareness is key to fostering a culture of safety.

So, what exactly constitutes proper power tool safety? It encompasses a range of practices, from choosing the right tool for the job to maintaining a safe work environment. It also includes understanding the specific safety mechanisms of each tool and using appropriate personal protective equipment (PPE).

One benefit of prioritizing power tool safety is, of course, injury prevention. Wearing safety glasses can prevent eye damage from flying debris, while using ear protection minimizes the risk of hearing loss from prolonged exposure to loud noises. Another advantage is increased productivity. When you're confident in your safety, you can focus on the task at hand, leading to more efficient and accurate work. Finally, practicing safe tool operation can extend the lifespan of your tools by preventing damage from misuse or improper handling.

Creating a safe work area is essential. Ensure adequate lighting and ventilation. Keep the area free of clutter and tripping hazards. Before starting any task, inspect your power tools for damage. Damaged cords, loose parts, or malfunctioning safety features should be addressed immediately.

Best Practices for Power Tool Safety:

1. Always wear appropriate PPE, including safety glasses, ear protection, and gloves.

2. Disconnect the power tool before changing blades or making adjustments.

3. Use the right tool for the job. Don't force a tool to perform a task it wasn't designed for.

4. Maintain a firm grip on the tool and use both hands whenever possible.

5. Secure your workpiece properly to prevent movement during operation.

Challenges and Solutions:

Challenge: Dust and debris inhalation. Solution: Wear a dust mask or respirator and use dust collection systems whenever possible.

Challenge: Kickback from saws. Solution: Use anti-kickback features and stand to the side of the blade, never directly behind it.

Advantages and Disadvantages of Implementing Power Tool Safety

| Advantages | Disadvantages |

|---|---|

| Reduced injuries | Can be time-consuming to implement initially |

| Increased productivity | Cost of PPE and safety equipment |

| Extended tool life | May require adjustments to workflow |

FAQs:

1. Q: What PPE should I wear when using power tools? A: Always wear safety glasses, hearing protection, and appropriate gloves. Consider a respirator or dust mask when working in dusty environments.

2. Q: What should I do if a power tool malfunctions? A: Immediately disconnect the tool from the power source and do not attempt to use it until it has been repaired by a qualified professional.

3. Q: How often should I inspect my power tools? A: Inspect your tools before each use, looking for any signs of damage or wear.

4. Q: Is it safe to use power tools in wet conditions? A: No, avoid using power tools in wet or damp conditions unless they are specifically designed for such use.

5. Q: What is kickback? A: Kickback is a sudden, violent reaction of a power tool, often caused by the blade binding or catching on the workpiece.

6. Q: How can I prevent kickback? A: Use anti-kickback features, maintain a firm grip, and stand to the side of the blade, never directly behind it.

7. Q: What should I do if I experience kickback? A: Release the trigger immediately and maintain control of the tool. Do not attempt to restrain the tool.

8. Q: Where can I learn more about power tool safety? A: Consult the manufacturer's instructions, online resources from OSHA, or local workshops and training centers.

Tips and Tricks:

Regularly clean your power tools to ensure optimal performance and prevent buildup of dust and debris that could compromise safety features.

In conclusion, prioritizing power tool safety is paramount for anyone who uses these powerful instruments. By adhering to established safety guidelines, investing in proper training, and maintaining a vigilant approach, you can significantly reduce the risk of injuries and create a safer and more productive work environment. Remember, safety is not an option; it's a necessity. Embracing a culture of safety empowers you to work confidently, efficiently, and with the peace of mind that comes from knowing you're protecting yourself and those around you. Don't just use your power tools – master them safely. Make safety a habit, not an afterthought. Invest in your safety today, and reap the rewards of a lifetime of successful projects.

Protecting young lives understanding mexicos general law of the rights of children

Unlocking connection the art of textual allure

Triple the bass mastering a 3 subwoofer car audio setup

Tips for Power Tool Safety - You're The Only One I've Told

power tool safety tips - You're The Only One I've Told

Tool Safety Quiz at Glenn Villarreal blog - You're The Only One I've Told

10 Safety Tips for Working with Hand and Power Tools - You're The Only One I've Told

Basic Safety Rules for Hand Tools - You're The Only One I've Told

Power tool safety tips - You're The Only One I've Told

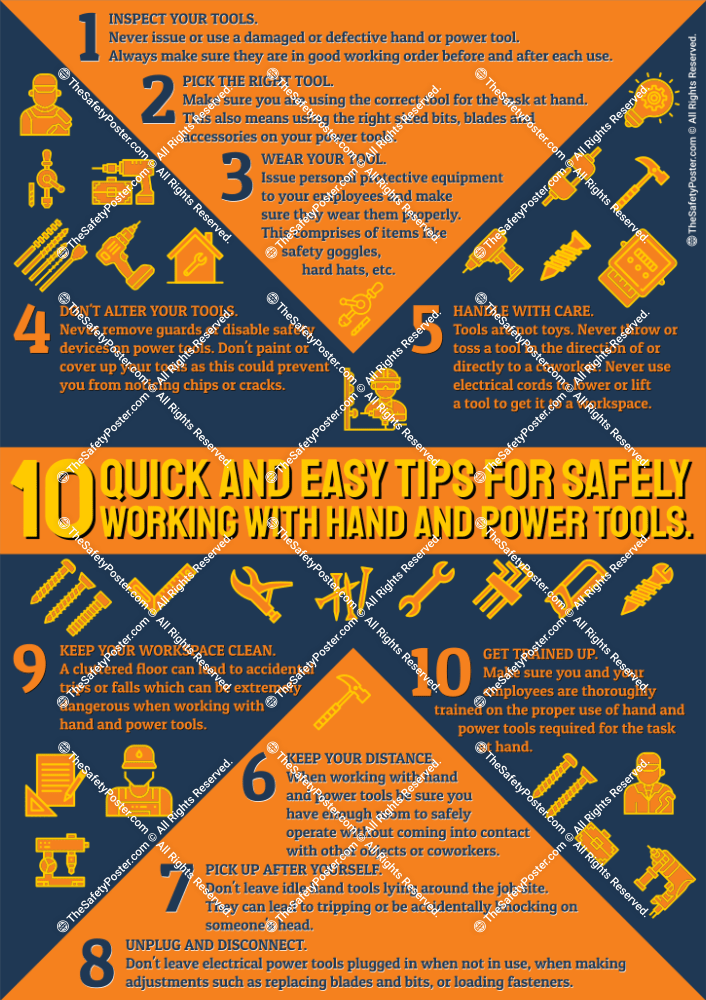

10 tips for safely working with hand and power tools - You're The Only One I've Told

Safety for power tools - You're The Only One I've Told

Toolbox Talk Hand Power Tool Safety - You're The Only One I've Told

10 Essential Tips for Power Tool Safety - You're The Only One I've Told

Hand And Or Power Tools Safety Program Template - You're The Only One I've Told

17 Safety Tips for Power Tools Use - You're The Only One I've Told

Tool Safety Videos at Sherry McCann blog - You're The Only One I've Told

Hand Tool Safety on Construction Sites - You're The Only One I've Told

Hand Tool Safety Tips - You're The Only One I've Told